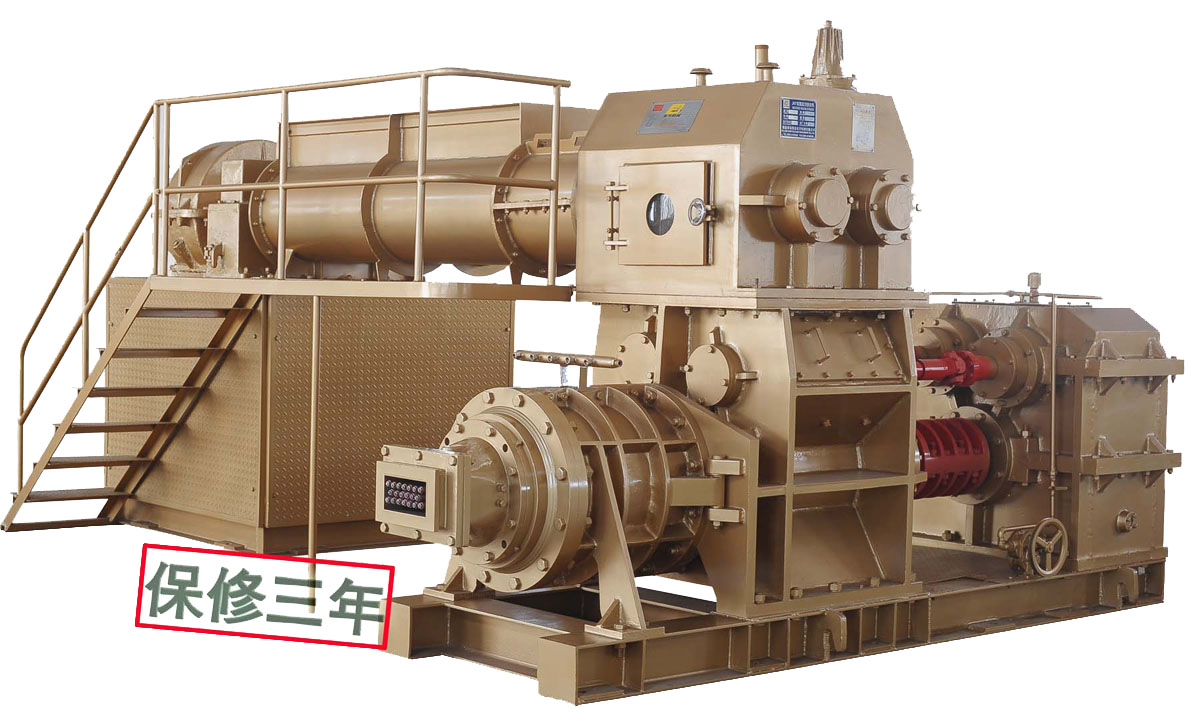

The JKY75-70 bipolar vacuum extruder is a combination vacuum hard plastic extrusion equipment manufactured by drawing on advanced foreign technology and processes, combined with the characteristics of domestic hard plastic extrusion, and equipped with a robot billet system. An automatic production line suitable for new wall materials with an annual output of 100-130 million (converted standard bri

The large section high-speed pneumatic multifunctional coding machine independently developed by Fujian New Oriental Machinery Co., Ltd. has a servo fully automatic control system that is efficient and stable. The robot coding machine, automatic coding system, and the new generation JKY70/65 large vacuum extruder are mature and stable in technology, suitable for tunnel kilns with a section of 4.6

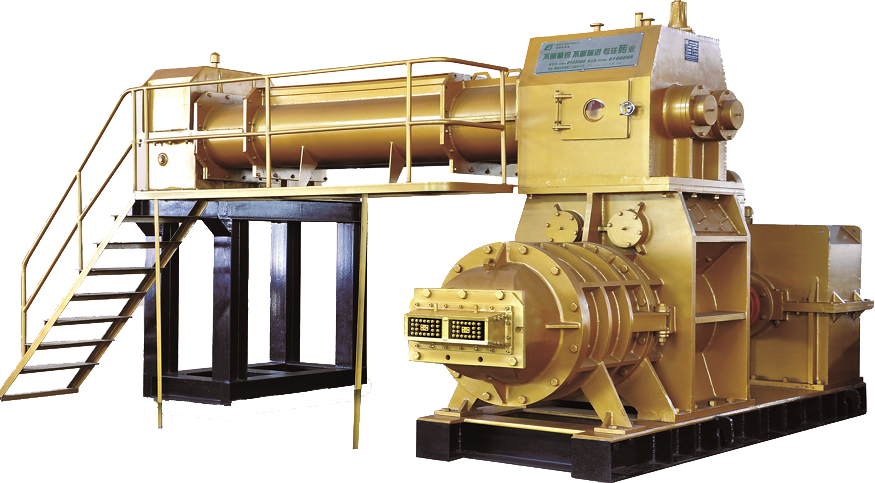

JKY75/70 and JKY60/60 large vacuum extruders are large two-stage vacuum extruders designed specifically for the production of porous bricks. The dual strip design process adopts vacuum extrusion and two-stage stirring. Two electric motors drive the split flow reducer machine through an axial pneumatic clutch, respectively driving the stirring extrusion and forming extrusion. Suitable for producing

JKY55-55 two-stage vacuum extruder is suitable for large vacuum brick machines designed for sintering hollow bricks with low plasticity clay as raw material. The product performance is stable and the output is high. Independent cast steel gearbox application effectively improves stability performance and product service life.